Mitigate Problems – Reduce Costs

The noise differences between trains have been shown to be excellent indicators for asset health and maintenance. Dynamic analysis of noise levels close to wheel-rail interface comparing trains in also across the same train can identify targets for inspection and remedy engineering issues before they become a significant problem to reliable service.

This Rail Noise/Asset Health Monitoring has multiple benefits:

- Autonomous operation for long periods (multi-year)

- Robust construction to operate in harsh outdoor environments

- Quick and easy to install

- Sense when a train is present then sample and analyze noise levels until the train has passed

- Periodically sample and analyze noise levels when no train is present

- Report average and standard deviation noise levels

- Report max X sound levels with time from the start of the train present event

- Communicate reports to a back-office system

Solution

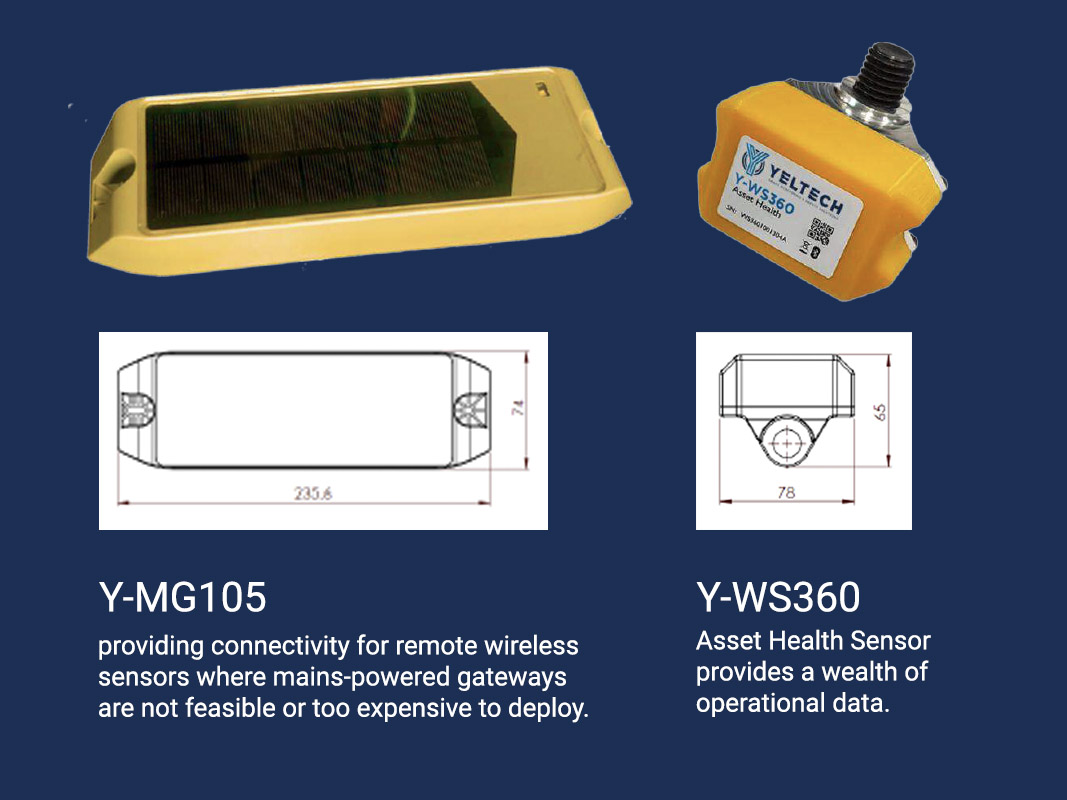

The Y-WS360 is a robust accurate sensor that can be placed close to the wheel-rail interface. It is easy to install with a magnetic mount. The self-powered Y-MG105 can be located close to the WS360 (e.g. within 30m) and positioned to have a clear sky for power generation. For monitoring in dark conditions, a rechargeable battery can support the operation for several months.