The Problem

The catenary and contact wires are installed in lengths that are tensioned at either end in order to keep the contact wire as still as possible. This is so that a good contact is maintained with the pantograph at all times and in all conditions.

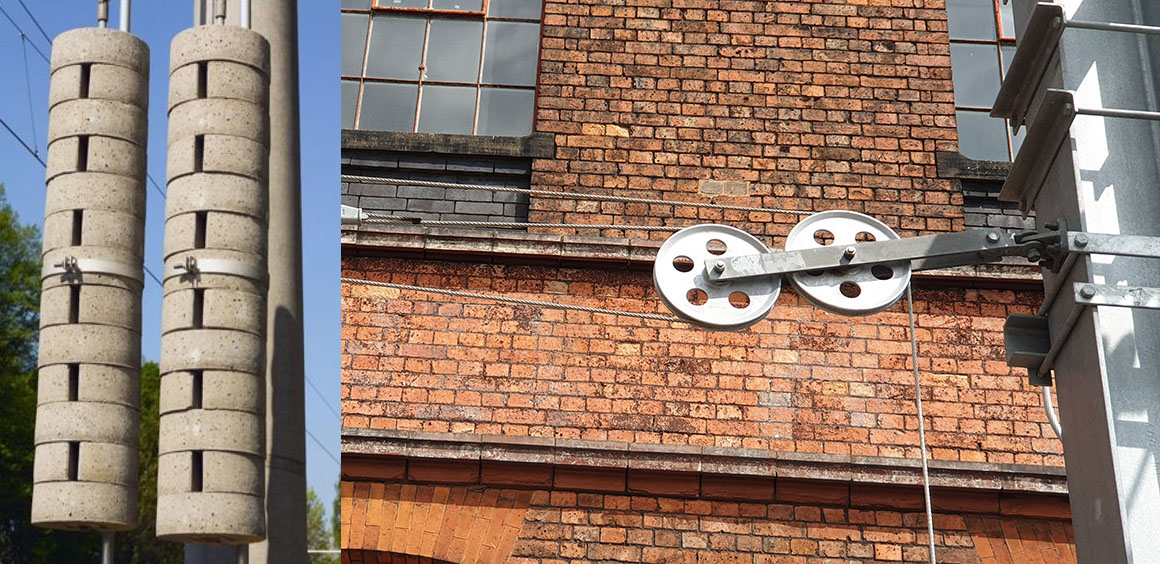

The conventional tensioning mechanism consists of a braced mast and iron weights. These weights move up and down according to the ambient temperature. This can affect the tensioning and can cause service disruptions.

Click/tap any image for a larger version

Solution 1: Wire Transducer

Using the YelTech Wire Transducer Sensor which is easy to install (in under 10 Minutes). This solution measures 3 key distances, is a lightweight compact design. This solution sends alerts to phone or email using the YelTech Cloud. The solution has a 3 to 5 year continuous battery life (depending on the frequency of transmissions). Data is easy to analyse via the Secure Cloud Dashboard allowing maintenance scheduling and mitigation of problems.

Solution 2: RADAR Position Sensor

Using RADAR Technology, the position sensor measures both the X & Y axes of the structure and the temperature. It is a lightweight unit, compact and easy to install (in under 10 seconds). Alerts sent to phone/email and the unit has 3 to 5 years of continuous battery use (depending on the frequency of transmissions). Data is easy to analyse using the YelTech Secure Cloud Dashboard. This device helps to mitigate dewirements and significant delays to services by measuring fixed termination lines during any weather, but particularly during hot seasons which results in reduced tension in the OLE environment.