Yeltech Pantograph and Power Line Monitoring Solution

A train pantograph is an apparatus mounted on the roof of an electric train, tram or electric bus to receive power from an overhead power line. Yeltech supply and support Broadsens’s ultra-low power wireless vibration and temperature sensors. These robust sensors can monitor the integrity of both the train pantograph and its contact with the power line. Real time vibration and temperature monitoring is provided by wireless sensor SVT400-V. Sensor cases can be customised to fit into all train pantographs.

Yeltech Pantograph and Power Line Monitoring Solution

A train pantograph is an apparatus mounted on the roof of an electric train, tram or electric bus to receive power from an overhead power line. Yeltech supply and support Broadsens’s ultra-low power wireless vibration and temperature sensors. These robust sensors can monitor the integrity of both the train pantograph and its contact with the power line. Real-time vibration and temperature monitoring is provided by wireless sensor SVT400-V. Sensor cases can be customised to fit into all train pantographs.

Yeltech Pantograph and Power Line Monitoring Solution

A train pantograph is an apparatus mounted on the roof of an electric train, tram or electric bus to receive power from an overhead power line. Yeltech supply and support Broadsens’s ultra-low power wireless vibration and temperature sensors. These robust sensors can monitor the integrity of both the train pantograph and its contact with the power line. Real-time vibration and temperature monitoring is provided by wireless sensor SVT400-V. Sensor cases can be customised to fit into all train pantographs.

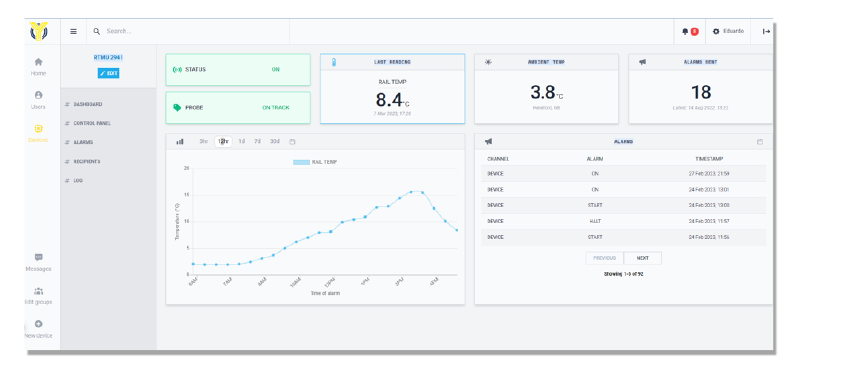

Rail Temperature Monitoring Unit – MK3

The RTM is an automatic temperature warning system designed to monitor the temperature of rails on railway tracks during the summer and winter months. The system uses sensors to measure the temperature of the rails continuously and alerts maintenance crews if the temperature exceeds pre-defined thresholds.

A system designed to avoid costly manual assessments, prevent service disruption caused by rail buckling/distortion, and mitigate accidents from derailments.

YELCloud Interface - accurate and easy to use

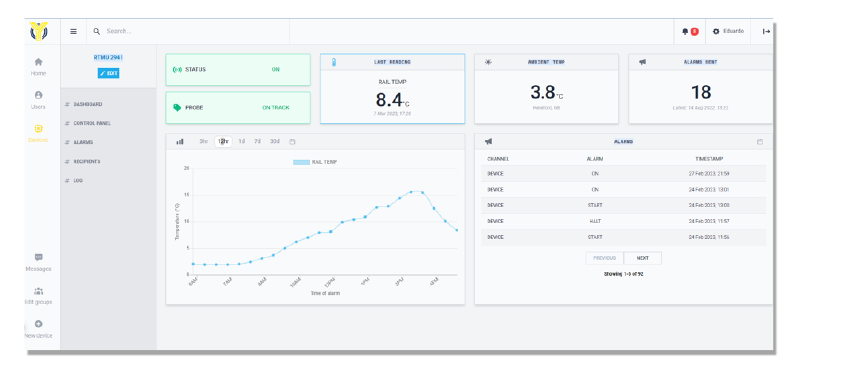

Rail Temperature Monitoring Unit – MK3

The RTM is an automatic temperature warning system designed to monitor the temperature of rails on railway tracks during the summer and winter months. The system uses sensors to measure the temperature of the rails continuously and alerts maintenance crews if the temperature exceeds pre-defined thresholds.

A system designed to avoid costly manual assessments, prevent service disruption caused by rail buckling/distortion, and mitigate accidents from derailments.

YELCloud Interface - accurate and easy to use

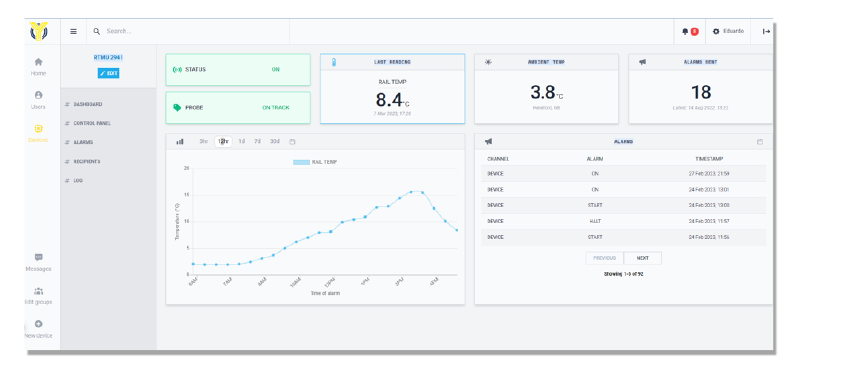

Rail Temperature Monitoring Unit – MK3

The RTM is an automatic temperature warning system designed to monitor the temperature of rails on railway tracks during the summer and winter months. The system uses sensors to measure the temperature of the rails continuously and alerts maintenance crews if the temperature exceeds pre-defined thresholds.

A system designed to avoid costly manual assessments, prevent service disruption caused by rail buckling/distortion, and mitigate accidents from derailments.

YELCloud Interface - accurate and easy to use

Yeltech Tilt System (TMS) – High-sensitivity Accelerometers

By replacing schedule-driven maintenance with condition-based maintenance, Yeltech’s Structural Tilt Monitoring System is able to observe changes in almost any setting and to be proactive in mitigating serious consequences.

The monitoring of structural behaviour can detect anomalies in real-time, therefore enabling maintenance and repair actions to be implemented more efficiently. This has a direct impact by reducing operating costs.

All structures are subject to internal and external factors that can cause wear and eventual malfunction. Targeting areas of concern with Yeltech’s Tilt Monitoring helps to ensure sound infrastructure.

- Yeltech’s TMS uses high sensitivity accelerometers

- Measures both the X & Y Axis of the structure, & temperature

- Lightweight unit

- Compact

- Easy to install (in under 5 Seconds)

- Alerts sent to phone/email

- 3 to 5 Years continuous battery use (depending on the frequency of transmission)

- Easy to use Secure Cloud Dashboard to analyse data for preventative maintenance

- Software compatible with all devices

- Built for 24/7 operation

Yeltech Tilt System (TMS) – High-sensitivity Accelerometers

By replacing schedule-driven maintenance with condition-based maintenance, Yeltech’s Structural Tilt Monitoring System is able to observe changes in almost any setting and to be proactive in mitigating serious consequences.

The monitoring of structural behaviour can detect anomalies in real-time, therefore enabling maintenance and repair actions to be implemented more efficiently. This has a direct impact by reducing operating costs.

All structures are subject to internal and external factors that can cause wear and eventual malfunction. Targeting areas of concern with Yeltech’s Tilt Monitoring helps to ensure sound infrastructure.

- Yeltech’s TMS uses high sensitivity accelerometers

- Measures both the X & Y Axis of the structure, & temperature

- Lightweight unit

- Compact

- Easy to install (in under 5 Seconds)

- Alerts sent to phone/email

- 3 to 5 Years continuous battery use (depending on the frequency of transmission)

- Easy to use Secure Cloud Dashboard to analyse data for preventative maintenance

- Software compatible with all devices

- Built for 24/7 operation

Yeltech Tilt System (TMS) – High-sensitivity Accelerometers

By replacing schedule-driven maintenance with condition-based maintenance, Yeltech’s Structural Tilt Monitoring System is able to observe changes in almost any setting and to be proactive in mitigating serious consequences.

The monitoring of structural behaviour can detect anomalies in real-time, therefore enabling maintenance and repair actions to be implemented more efficiently. This has a direct impact by reducing operating costs.

All structures are subject to internal and external factors that can cause wear and eventual malfunction. Targeting areas of concern with Yeltech’s Tilt Monitoring helps to ensure sound infrastructure.

- Yeltech’s TMS uses high sensitivity accelerometers

- Measures both the X & Y Axis of the structure, & temperature

- Lightweight unit

- Compact

- Easy to install (in under 5 Seconds)

- Alerts sent to phone/email

- 3 to 5 Years continuous battery use (depending on the frequency of transmission)

- Easy to use Secure Cloud Dashboard to analyse data for preventative maintenance

- Software compatible with all devices

- Built for 24/7 operation

Yeltech Waste Management Monitoring with SLOC

IoT sensors play a key role in transforming the waste management industry to a sustainable and resource-efficient future. Yetlech’s SLOC IoT device solution digitise and optimise waste management by avoiding overfilled bins and inefficient waste collection. This reduces CO₂, noise and congestion and keeps mustering and collection points clean.

IoT sensors are revolutionising the waste disposal industry. Smart sensors are able to continuously collect data on fill levels, waste compactors and recycling facilities. The cost and environmental impact of inefficient waste collection for both recycling and landfill can be reduced using innovative Yeltech solutions.

Yeltech Waste Management Monitoring with SLOC

IoT sensors play a key role in transforming the waste management industry to a sustainable and resource-efficient future. Yetlech’s SLOC IoT device solution digitise and optimise waste management by avoiding overfilled bins and inefficient waste collection. This reduces CO₂, noise and congestion and keeps mustering and collection points clean.

IoT sensors are revolutionising the waste disposal industry. Smart sensors are able to continuously collect data on fill levels, waste compactors and recycling facilities. The cost and environmental impact of inefficient waste collection for both recycling and landfill can be reduced using innovative Yeltech solutions.

Yeltech Waste Management Monitoring with SLOC

IoT sensors play a key role in transforming the waste management industry to a sustainable and resource-efficient future. Yetlech’s SLOC IoT device solution digitise and optimise waste management by avoiding overfilled bins and inefficient waste collection. This reduces CO₂, noise and congestion and keeps mustering and collection points clean.

IoT sensors are revolutionising the waste disposal industry. Smart sensors are able to continuously collect data on fill levels, waste compactors, and recycling facilities. The cost and environmental impact of inefficient waste collection for both recycling and landfill can be reduced using innovative Yeltech solutions.

Get in touch

We would love to hear from you.

We offer a wide range of monitoring solutions across a wide range of industries. If you don’t immediately see a solution for your industry/application, then contact us. Either email or call or complete the form on this page.

Email: info@yeltech.com

Tel: +44 (0) 845 052 3860

Building 2

Guildford Business Park

Guildford

Surrey

GU2 8XH

UK

… just some of our key partners

Our latest news…

A Game Changing Collaboration

Driving Smarter, Safer Solutions Together. Earlier this year, Yeltech partnered with Sunbelt Rentals UK—one of the country’s leading names in equipment hire and infrastructure services—to expand access to smarter monitoring and safety solutions across the UK.

The Future of Bogie, Bearing, and Track Monitoring

Predictive insights that keep rail networks safer, faster, and more reliable. The railway industry has always faced a balancing act—maximizing safety and efficiency while minimizing downtime and costs. That’s where Yeltech’s smart monitoring solutions step in.

Powering the World’s Longest Driverless Train Network!

We are proud to be part of the groundbreaking Riyadh Metro, officially launched in November 2024. Spanning 176 km across six lines, it now holds the title of the world’s longest driverless train network, serving 1.2 million passengers daily with capacity expected to rise to 3.6 million in the near future.